As machinery becomes more advanced, so do the demands for better protection, efficiency, and performance. That’s where nano-lubricants step in—revolutionizing the way we care for engines and industrial equipment. By using microscopic particles to reduce friction, boost durability, and extend service life, nanotechnology-based lubricants are setting a new standard in modern maintenance.

At Fubex Lubricants, we provide premium nano lubricants for superior engine protection and performance. Enjoy fast shipping, price match guarantee, and expert support at +971 50 544 9614.

In this article, we explore how these innovative solutions are transforming industries and shaping the future of lubrication.

What Are the Benefits of Nanotechnology-Based Grease?

Nanotechnology-based grease is changing the way industries handle maintenance. With its advanced formula, it reduces effort, saves time, and increases overall efficiency—making it a game-changer in industrial lubrication.

Superior Lubrication Performance

The primary role of grease is to reduce friction between moving machine parts. Nanotechnology-based grease uses nanoparticles that fill surface irregularities more effectively than traditional grease. This ensures a smoother, more consistent lubrication layer, reducing wear and tear, minimizing equipment breakdowns, and extending machinery life.

Improved Temperature Stability

Friction generates heat, which can lead to dangerous temperature spikes and even industrial fires. Nano-enhanced grease offers excellent heat dissipation, helping machinery stay cool even under extreme operating conditions. This prevents overheating and supports reliable performance in high-temperature environments.

Better Energy Efficiency

Thanks to reduced friction, equipment using nano grease consumes less energy. Lower resistance means motors and components run more smoothly, cutting down energy use and operational costs—an important benefit for industries focused on efficiency.

Promotes Sustainable Practices

By protecting machinery components and extending the time between lubricant applications, nanotech grease helps reduce waste and lowers the demand for conventional lubricants. This contributes to more eco-friendly and sustainable industrial operations.

Resistant to Harsh Environments

Nanotechnology grease is highly resistant to water, dust, and extreme temperatures, making it ideal for heavy-duty applications such as mining, offshore drilling, and manufacturing. It maintains its performance even in the toughest environments.

Nanotechnology-based grease delivers outstanding performance, energy savings, and environmental benefits. It’s a smart, high-quality, and sustainable solution for modern industrial lubrication—providing both efficiency and long-term value.

Recent Innovations in Lubrication Technology

Modern lubrication is evolving rapidly, thanks to new technologies designed to boost performance, reduce wear, and promote sustainability. Below are some of the latest innovations transforming the industry.

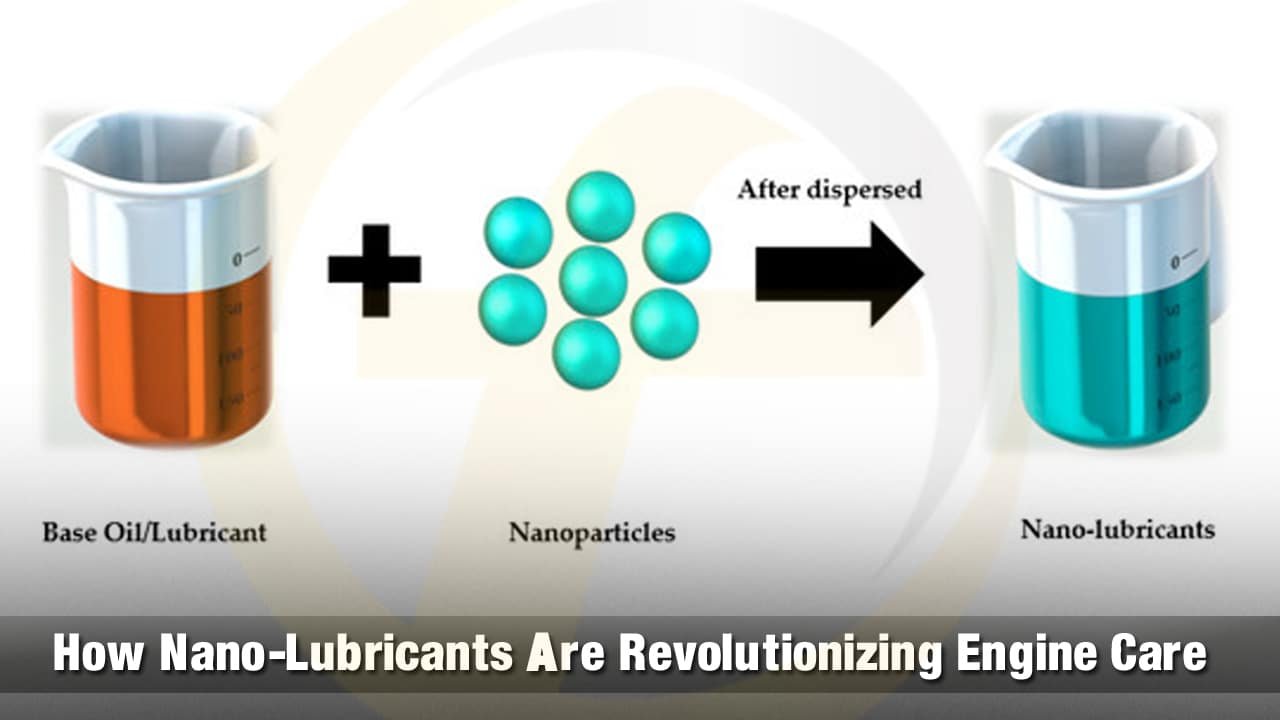

Nano-Lubricants

One of the most advanced developments is the use of nano-lubricants. These lubricants are enhanced with nanoparticles like graphene, molybdenum disulfide, and carbon nanotubes. The result? Significantly reduced friction, better load-bearing capacity, and improved thermal stability—making nano-lubricants ideal for high-performance industrial applications.

Ionic Liquids

Ionic liquids are cutting-edge lubricants made from salts that remain liquid at room temperature. They are non-flammable, non-volatile, and offer exceptional thermal and chemical stability. Their unique properties make them perfect for high-pressure and high-temperature environments such as aerospace systems and heavy machinery.

Bio-Based Lubricants

As industries shift toward eco-friendly solutions, bio-based lubricants have emerged as a strong alternative. Made from renewable resources like vegetable oils and animal fats, these lubricants are biodegradable and less toxic. Ongoing innovations have improved their oxidation resistance and performance, making them suitable for various applications without compromising on efficiency.

Smart Lubrication Systems

The rise of digital technology has introduced smart lubrication systems. These systems use sensors to monitor lubricant condition in real time—tracking viscosity, temperature, and contamination levels. This data enables predictive maintenance, reduces unexpected downtime, and extends the service life of critical equipment.

Future Trends and Advances in Lubrication Technology

Lubrication technology is moving toward smarter, more efficient, and longer-lasting solutions. Here are two key innovations shaping the future of the industry.

Self-Healing Lubricants

One exciting development is the creation of self-healing lubricants. These advanced lubricants are designed with microcapsules containing restorative agents. When the lubricant experiences wear or damage, the capsules break open and release the healing compounds—automatically restoring the lubricant’s protective properties. This helps extend the service life of machinery and reduce the need for frequent reapplication.

Next-Generation Additives

The future of lubrication also includes the rise of advanced additive technologies. These cutting-edge additives boost the performance of base oils by offering stronger protection against wear, corrosion, and oxidation. Some even enhance energy efficiency, helping machinery run smoother while lowering fuel and power consumption.

The Impact of New Lubrication Technologies

Modern lubrication technologies are reshaping the way industries operate—offering better performance, sustainability, and cost-effectiveness.

Improved Performance and Efficiency

New-generation lubricants are designed to reduce friction, minimize wear, and boost overall system efficiency. In both the automotive and engineering sectors, these innovations lead to smoother operation, longer service intervals, and increased reliability of equipment.

Eco-Friendly Advantages

The adoption of bio-based and synthetic lubricants supports environmental goals by reducing harmful emissions and minimizing waste. These lubricants help lower the carbon footprint of vehicles and industrial machinery, making them a cleaner choice for sustainable operations.

Long-Term Cost Savings

Although advanced lubricants may come with a higher initial price, they deliver major long-term value. Benefits include reduced maintenance, fewer breakdowns, and extended equipment life—resulting in significant cost savings for both businesses and end-users.

Key Industries That Depend on Advanced Lubrication Technology

Lubrication technology is essential to the smooth operation of mechanical systems across a wide range of industries. From automotive engines to industrial turbines, advanced lubricants help reduce wear, improve efficiency, and extend equipment life. Here are some of the major industries that rely on cutting-edge lubrication solutions:

Automotive Industry

The automotive sector is one of the largest users of lubrication technology. From engines and transmissions to suspension systems, every moving part requires proper lubrication. Innovations like synthetic oils and smart lubrication systems have boosted vehicle performance, reduced wear, and increased fuel efficiency. High-performance engines especially need lubricants that can withstand extreme heat and pressure while maintaining protection against friction and breakdown.

Manufacturing & Industrial Machinery

In manufacturing, continuous operation of machinery is key to productivity. Equipment like conveyor belts, CNC machines, and hydraulic presses depend on high-performance industrial lubricants to minimize downtime and reduce mechanical stress. Advanced lubricants with excellent thermal stability and load-bearing capacity ensure optimal performance even under high-speed, high-load conditions.

Aerospace Industry

The aerospace industry demands the most reliable lubrication solutions due to the extreme conditions aircraft face. Lubricants used here must function flawlessly at high altitudes, under rapid temperature shifts, and intense mechanical pressure. Synthetic and nano-lubricants are widely used in jet engines, landing gear, and hydraulic systems to ensure safety, precision, and durability in flight.

Energy Production

Whether it’s a thermal power plant or a wind turbine, energy production facilities rely on durable lubricants to keep operations running smoothly. Turbines, generators, and rotating equipment need lubricants that can resist extreme temperatures and high pressure. Using the right lubrication helps reduce energy loss, extend equipment life, and improve overall efficiency.

Marine Industry

The marine industry faces tough environmental challenges such as saltwater exposure, humidity, and extreme temperatures. Marine engines, propellers, and onboard equipment rely on specialized marine lubricants to prevent corrosion and maintain performance. These lubricants are designed to handle heavy loads and long operating hours in harsh offshore and maritime environments.

Food and Beverage Industry

In the food and beverage sector, lubrication is essential for processing, packaging, and handling machinery. Food-grade lubricants are specially formulated to meet hygiene standards and regulatory requirements. They offer excellent resistance to water, oxidation, and temperature changes—while being safe for incidental contact with food products.

Across all these industries, advanced lubrication technology plays a vital role in ensuring safety, efficiency, and reliability. At Fubex Lubricants, we continue to support these sectors with innovative, high-performance lubrication solutions tailored to meet their unique challenges.

Final Takeaways

Nano-lubricants are redefining engine care and industrial maintenance with unmatched efficiency, durability, and eco-friendliness. From reducing friction to enabling smart, self-healing systems, these advanced solutions are powering the future of performance and protection. At Fubex Lubricants, we’re proud to be part of this revolution—bringing cutting-edge lubrication technology to every industry we serve.

FAQs

Q1: What is the main purpose of using lubricant oil in engine moving parts?

The main purpose is to reduce friction and wear between moving engine parts. Lubricant oil keeps components running smoothly, even under high heat and pressure.

Q2: Can nanoparticles be added to engine oil?

Yes, nanoparticles can be added to engine oil as additives to enhance lubrication, reduce friction, and minimize engine wear.

Editor-at-Large

A passionate writer in the lubricant industry, Awais Iqbal has been covering oils, greases, and industrial fluids since the start of his career. At 25, he’s already written for blogs, catalogs, and brand guides across the UAE. Awais’s insights help companies connect with their audience, and his clear, helpful writing style is trusted by brands in the region.