When it comes to industrial operations, choosing the proper lubricant is essential for performance, safety, and efficiency. Water-based lubricants have become increasingly popular in various industries, especially where high heat and cleanliness are concerns. But are they safe and effective for heavy-duty applications?

At Fubex Lubricants, we provide premium-quality lubricants suitable for all engine types. Benefit from fast delivery, a price match guarantee, and hassle-free returns. Not sure which oil is right for your engine? Call us at +971 50 544 9614 — our expert team is here to help!

In this article, we’ll explore the benefits, composition, application methods, and safety of water-based plunger lubricants—so you can make informed decisions for your machinery and processes.

Key Benefits of Water-Based Lubricants

1. Better Casting Quality

Water-based lubricants help achieve cleaner, higher-quality castings. Unlike traditional oil-based options, they reduce stains and porosity, leading to smoother and more consistent finished products. With less contamination during the casting process, manufacturers can expect improved surface quality and fewer defects.

2. Increased Safety in High-Heat Environments

Safety is crucial in die casting, especially when working with extreme heat and molten metals. Water-based lubricants are much less flammable than oil-based ones, significantly lowering the risk of fire or hazardous incidents. This makes them a safer choice in high-temperature industrial settings.

3. Cleaner and Safer Workspaces

Traditional lubricants often cause oily residues and spills, making the workspace slippery and hazardous. Water-based plunger oils reduce these issues by offering a cleaner application with minimal residue. The result is a tidier, safer, and more operator-friendly Environment.

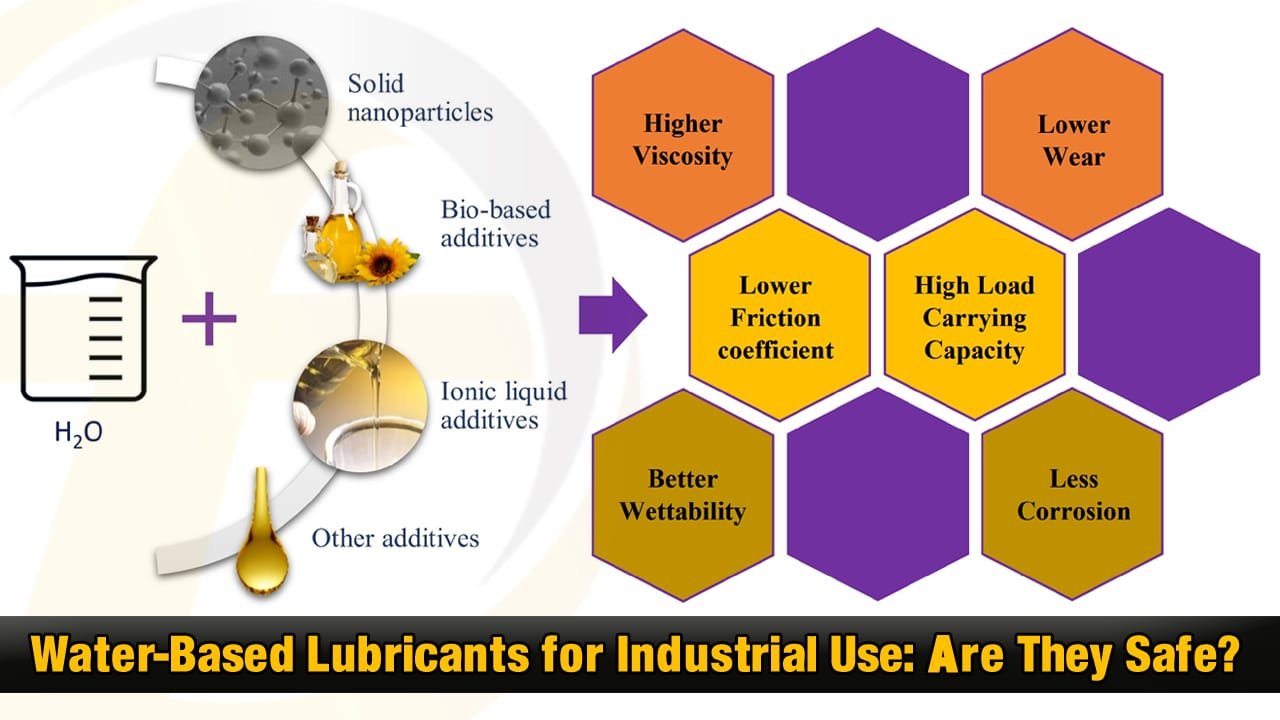

Composition and Functionality of Water-Based Lubricants

1. Core Ingredients

Water-based lubricants primarily use water as the base, serving as a carrier for critical functional components. These include emulsified mineral oils, extreme pressure (EP) additives, and solid lubricants like PTFE or graphite. While water doesn’t provide lubrication on its own, it efficiently delivers these agents to the plunger sleeve or tip, ensuring smooth and adequate lubrication during the casting process.

2. Role of Water as a Carrier

Water’s primary purpose in the formula is to act as a transport medium. It carries oils, additives, and solid lubricants precisely to the necessary points, reducing waste and avoiding over-application. This controlled delivery helps lower the risk of casting defects and supports a cleaner, more efficient working environment.

Application Methods of Water-Based Lubricants

1. Drip Application

In the drip method, the lubricant is applied slowly to either the retracted plunger tip or sleeve. This approach offers precise control over how much lubricant is used, minimizing over-lubrication and keeping the process clean and efficient.

2. Atomization or Spray Application

The spray method disperses the lubricant as fine droplets over the plunger area, ensuring even coverage across all key lubrication points. This technique is especially effective in high-speed or automated systems where consistent application is essential for optimal performance.

How to Select the Right Industrial Lubricant

Choosing the proper industrial lubricant is essential for maintaining equipment performance, reducing wear, and extending machinery life. Below are key factors to consider when selecting the best lubricant for your operations:

1. Type of Machinery

Different machines have different lubrication requirements. For example, heavy-duty machinery often needs high-viscosity oils to handle pressure and load, while hydraulic systems require specially formulated oils that ensure smooth power transmission.

2. Operating Environment

Consider the working conditions your equipment is exposed to. Extreme temperatures, heavy loads, humidity, or corrosive environments all influence the type of lubricant needed. In such cases, you may need high-temperature or corrosion-resistant lubricants to ensure reliable performance.

3. Lubricant Type

Based on your equipment and industry, choose the appropriate form of lubricant—whether it’s oil-based, grease, or a synthetic formulation. Each type serves a different purpose and offers unique benefits in terms of durability, performance, and resistance to breakdown.

Key Benefits of Lubricants in Industrial Applications

Using the right industrial lubricants brings multiple advantages that directly enhance equipment performance and business productivity. Here’s how:

1. Friction Reduction

Lubricants create a protective layer between moving parts, significantly reducing friction. This leads to smoother operation and improved mechanical efficiency.

2. Longer Equipment Lifespan

By minimizing wear, corrosion, and surface damage, lubricants help extend the service life of machines and critical components.

3. Improved Energy Efficiency

Less friction means less power is needed to run machinery. High-quality lubricants can lower energy consumption, helping industries reduce operating costs.

4. Protection from Heat and Corrosion

Many industrial lubricants are engineered to perform under extreme temperatures and in corrosive environments. They shield machines from damage caused by heat or chemical exposure.

5. Lower Maintenance Costs

Reliable lubrication reduces the need for frequent repairs and part replacements. This not only cuts maintenance expenses but also minimizes downtime and boosts overall productivity.

Lubricants for the Metalworking Industry

In metalworking, lubricants are essential during high-friction processes like cutting, milling, drilling, and grinding. These specialized lubricants are designed to:

- Withstand intense heat and pressure.

- Improve surface finish and machining accuracy.

- Extend the life of cutting tools.

- Reduce the risk of thermal distortion in workpieces.

Choosing the proper metalworking lubricant ensures smoother operations and greater output quality in demanding industrial environments.

Best Lubricants for Industrial Machinery

The best lubricants for industrial machines are those formulated to handle harsh working conditions—mechanical stress, heavy loads, high speeds, and extreme temperatures. Commonly used industrial lubricants include:

- Hydraulic oils – for power transmission and system protection

- Bearing lubricants – to reduce friction and wear in rotating components.

- Gear fluids – for efficient load handling and gear protection

Each lubricant is specifically developed to match the operational demands of your machinery and ensure peak performance.

Final Takeaways

Water-based lubricants offer a safer, cleaner, and more efficient alternative to traditional oil-based options, especially in high-temperature industrial settings. From improving casting quality to minimizing maintenance costs and enhancing workplace safety, their benefits are clear.

Whether you’re working in die casting, metalworking, or heavy machinery operations, selecting the right lubricant plays a key role in performance and productivity. At Fubex Lubricants, we’re committed to providing high-quality lubrication solutions tailored to your industry needs. For expert guidance and premium products, trust Fubex to keep your machines running smoothly and safely.

FAQs

Q1: What’s the difference between industrial oil and grease?

Industrial oil is a liquid lubricant typically used in closed systems like engines, hydraulic units, and gearboxes. Industrial grease, on the other hand, is a thicker lubricant designed to stay in place for more extended periods, ideal for components like bearings, joints, and linear guides where reapplication is less frequent.

Q2: When should I use high-temperature lubricants?

High-temperature lubricants are essential when your equipment runs in extreme heat, such as in metalworking, furnaces, or smelting operations. These specialized lubricants resist thermal breakdown and protect parts from damage caused by excessive temperatures.

Q3: How can I maximize machine lifespan using industrial lubricants?

To extend the life of your machines, always choose the correct lubricant for each application, follow the recommended maintenance schedule, and routinely check the lubricant’s condition. Clean, uncontaminated, and properly applied lubricants help prevent wear and maintain peak performance.

Editor-at-Large

A passionate writer in the lubricant industry, Awais Iqbal has been covering oils, greases, and industrial fluids since the start of his career. At 25, he’s already written for blogs, catalogs, and brand guides across the UAE. Awais’s insights help companies connect with their audience, and his clear, helpful writing style is trusted by brands in the region.