Temperature control of hydraulic oil is crucial because it determines the efficiency of your machines. The oil in the machine should not heat up; if it does heat up, it decomposes, meaning that it forms a leak, which makes the machine not work properly.

If the oil is too cold, it becomes very thick, slowing it down. In this guide, you will find out why you need to select hydraulic oil temperature, what can cause it to increase, and how to cool it so that your equipment operates problem-free.

Importance of Maintaining Optimal Hydraulic Oil Temperature

Hydraulic oil begins to degrade when the temperature exceeds 140°F. If the temperature increases to another 15°F, it is over, and the life of the oil is reduced. At 155°F, the oil life is reduced in half; at 170°F, the life is reduced in half again. This is because oil degrades more frequently at high temperatures.

That is why having a temperature gauge in your system is much more than an indicator on the car’s dashboard. It is very useful in ensuring the oil’s health and stability of your system all in one.

It is always advisable to monitor and document the temperature of your system because it fluctuates depending on the weather or the location of the tank. It is possible to monitor it to avoid such occurrences before they even occur.

Impact of High Hydraulic Oil Temperature on Equipment Performance

If hydraulic oil becomes less dense, there is increased leakage within the system and such components as pumps perform poorly. Less viscous fluids decrease the strength of the oil layer to offer the required amount of lubrication to the parts in contact, increasing the chances of corrosion.

When getting thinner, the above system does not work as it should due to the thinning of the oil. The hydraulic cylinder may put out too much or very little force, erratically causing the whole machine to function. If the motor is slowed down to lower speeds, it executes a start and stops motion, affecting the smoothness of movement.

When the oil is too hot, the other components within the system can expand, thus altering the structure of the connections. This can cause any part to jam or cease to perform in the optimal manner it had been before.

Hot oil also ages faster. The oil’s useful life is reduced by half for every 10-minute rise in temperature above 65°C. Heat can also cause rubber seals to degrade faster, threatening the seals’ efficiency and the whole system.

Why Does Hydraulic Oil Temperature Matters?

- Performance and Efficiency: Hydraulic systems work best when the oil is at the right temperature. If the oil gets too hot, it becomes thinner, which makes the system less efficient and causes leaks. If the oil is too cold, it ignites slowly, slowing the system down and using more energy.

- Component Lifespan: Excessive heat in the engine can boil the oil faster and affect other engine components such as seals, pumps and valves. Hot oil tends to collect and cause the wear and tear of the equipment to be faster within a given period, reducing the equipment’s life cycle.

- Safety: It is unhealthy to overwork the system; the system might end up burning or producing a result that is not near what had been input. Letting the oil get to that temperature is dangerous, but keeping everything running safely is good.

What Affects Hydraulic Oil Temperature?

- Outside Temperature: In this case, the temperature around the system is a very critical factor. The oil can become hotter depending on how hot it is outside or whether this system is installed somewhere very small and cramped with little air movement.

- How You Use the System: Depending on the load you put on the system – in other words, if the system has to carry heavy things, run for a long time or move fast, it generates heat. Such systems require improved cooling to prevent the temperature from rising.

- System Design: Properties of the hydraulic system, such as the size and type of parts in its construction, determine its heat production and cooling capability level. Loading and an ill-designed system may overheat more easily or be more prone because of the flexibility.

Ways to Keep Hydraulic Oil Temperature Under Control

Use Coolers and Heat Exchangers

Adding coolers or heat exchangers is a great way to stop hydraulic oil from getting too hot. These devices take the extra heat from the oil and move it to air or water to keep the system at the right temperature.

Bigger Reservoirs

The reservoir holds the oil and helps cool it down. Larger reservoirs allow the heat to spread out and cool off. Adding special cooling fins can also help get rid of heat faster.

Good Airflow

Ensuring air can move around the hydraulic parts helps cool them down. Fans or blowers can improve airflow, especially in tight or stuffy spaces.

Regular Check-Ups

Keeping the system clean and well-maintained helps control the oil temperature. Change filters, check hoses for leaks, and make sure the oil is in good shape to avoid overheating.

Insulate the Parts

Wrapping hydraulic parts with insulation helps control the temperature. In cold places, it keeps the heat in; in hot places, it stops too much heat from building up.

Use the Right Oil

Choose the right oil to handle high and low temperatures. Using good-quality oil helps the system work better and last longer.

Keeping an Eye on Temperature and Finding Problems

It’s really important to use tools to check the temperature of hydraulic oil. By putting in temperature sensors and gauges, workers can watch the oil temperature closely and find any problems before they get too big. Some advanced systems can even give updates and alerts in real-time, so workers can act quickly to stop the oil from overheating.

How Hydraulic Oil Temperature Affects Your Equipment?

Keeping hydraulic oil at the right temperature prevents overheating and damaging your machines. If the temperature is too high, it can cause several problems:

- Sludge Buildup: When hydraulic oil gets too hot, it can become a thick goo called sludge. This sludge can get into the hydraulic cylinders and make everything work less efficiently, leading to breakdowns.

- Oil Thickness Changes: Heat can change how thick the hydraulic oil is. If it gets too thin, it won’t lubricate the parts as well, which can cause leaks.

- Hose and Seal Damage: High temperatures can make hoses and seals hard or even break them. This can lead to leaks and make the equipment wear out faster.

Tips for Keeping Hydraulic Fluid Temperature Safe

How hot is hydraulic oil too hot? Usually, if it gets over 140°F (60°C), that’s a warning sign, and serious damage can happen at about 180°F (82°C). Different hydraulic fluids can handle different temperatures, so always check what your specific fluid can take.

Here are some simple tips to help keep your hydraulic oil from getting too hot:

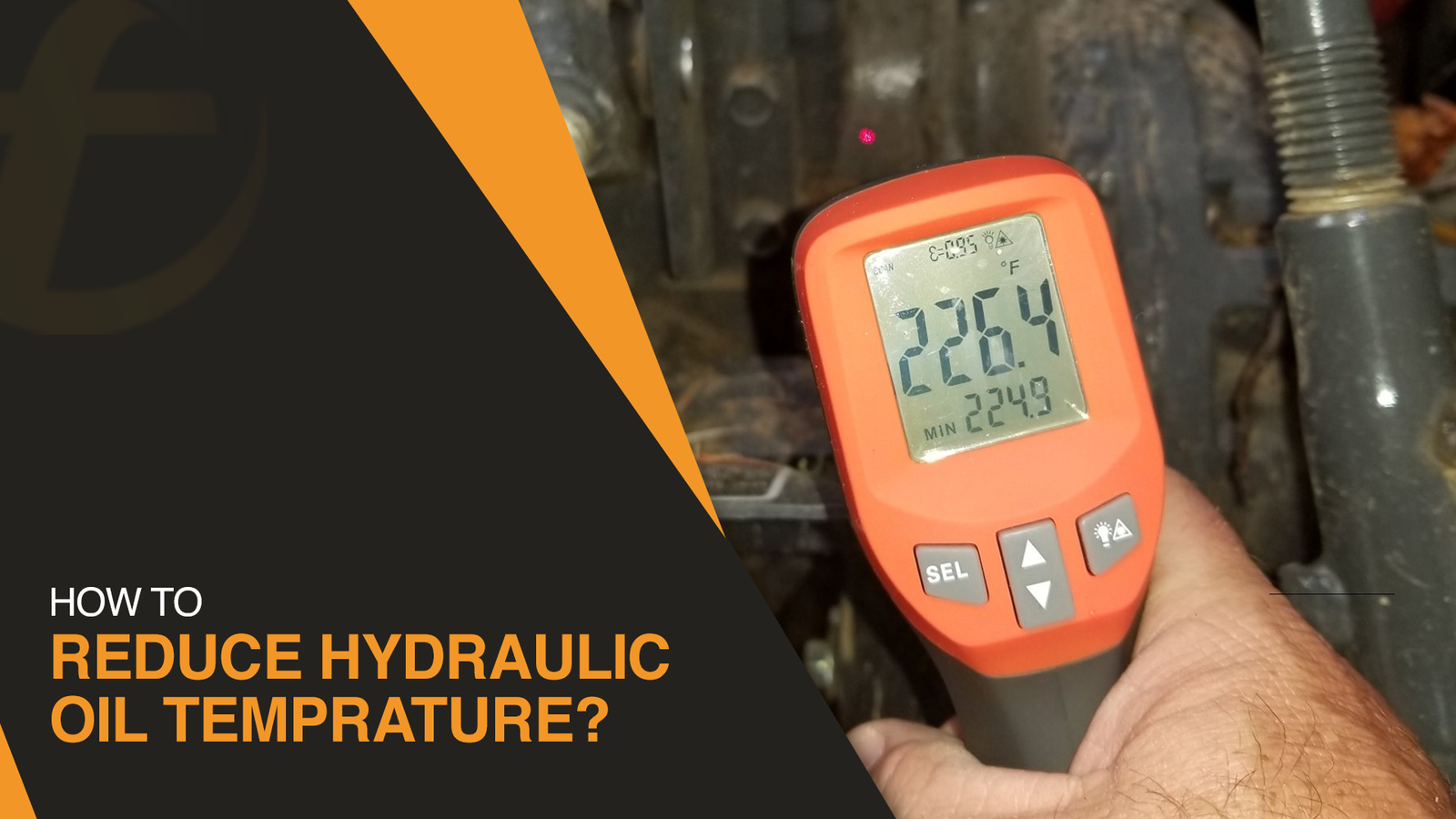

- Use a Heat Exchanger: This special device helps cool down the oil. You can use an infrared thermometer to see if your system is properly removing heat.

- Pick the Right Fluid: Make sure you’re using hydraulic oil that’s the right thickness (we call that viscosity) for your machine. In really hot or cold situations, you might need thicker oil.

- Check Oil Levels: Look at how much oil is in your system. If it’s too low, add clean oil. Low oil can cause the system to overheat.

- Look at the Oil: Check your hydraulic fluid for dirt or sludge. If you find any, it’s time to change it.

- Check for Leaks: Regularly check the seals and hoses for leaks or wear. Fixing these can help keep everything working well.

Bottom Line

To sum it up, checking the temperature of the hydraulic oil means your machinery and equipment endure longer in optimum conditions and perform more efficiently. You can do this by flushing the oil and ensuring enough air circulation in the area where the machine is located or using coolers.

Indeed, the best thing depends on the care, particularly the temperature, to avoid any issues and properly function. If you require assistance or to pursue a professional upgrade, Fubex Lubricants is ready to assist you!

Keep your machines working great and lasting longer—pick Fubex Lubricants Hydraulic Oil for the best protection and performance!

FAQs

Q1: How does excessive hydraulic oil temperature impact equipment longevity?

Ans: This is because when hydraulic oil is very hot, the parts of the machine expand. This results in the misfitting of the parts, which causes them to break or get stuck as they were initially intended to interconnect.

When this happens, it does not operate as an actuator, which is the component that makes things move. Furthermore, when the oil is extremely hot, the substance can deteriorate and thus will not be effective for long.

Q2: What are the primary signs of hydraulic system overheating?

Ans: Some of the more obvious symptoms that suggest a hydraulic system is overheating are readings that are higher than normal on the temperature gauge, unusual sounds such as whining or grinding and sluggish movement of the machine. You also may smell the burnt aroma of the oil or experience leaks if the seal fails. Sometimes, one can notice certain inefficiency in the machine’s performance, which might imply that the machine is on the verge of overheating.

Q3: How can you lower the temperature of hydraulic oil?

Ans: To cool down hydraulic oil that’s getting too hot, you can do two things: to cool more heat or prevent the heat from becoming worse. It helps to cool the oil by looking at the container where it is kept or stored. Just ensure that there is enough oil in it. If the oil is Exhausted, add it up to the right level. This goes a long way in maintaining low temperatures.